| Art.NO. | WLL/Pair(t). | Steel plate Thickness(mm) | Size | Weight kg | |||||||||

| A(mm) | B(mm) | C(mm) | D(mm) | F(mm) | G(mm) | H(mm) | I(mm) | R(mm) | L(mm) | ||||

| SVC1 | 1 | 0-20 | 129 | 35 | 27 | 36 | 137 | 33 | 12 | 55 | 33 | 245 | 3.5 |

| SVC2 | 2 | 0-25 | 153 | 44 | 31 | 50 | 165 | 42 | 16 | 62 | 43 | 312 | 6.5 |

| SVC3.2 | 3.2 | 0-35 | 173 | 50 | 39 | 60 | 212 | 48 | 18.5 | 76 | 53 | 363 | 12.5 |

| SVC5 | 5 | 0-50 | 209 | 62 | 45 | 68 | 236 | 68 | 24 | 92 | 61.5 | 419 | 17 |

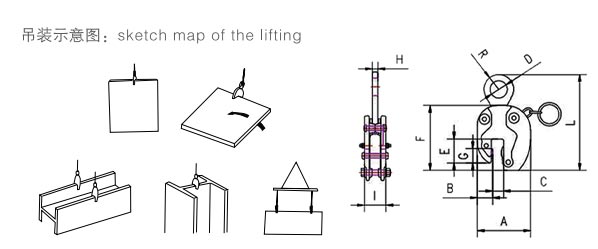

Application: vertical lifting of steel plate.

The high-quality metal alloy steel precision forging.

Loading range: 0-8ton.

One piece of clamps is used for the testing, and 1 pieces or 2 pieces are recommended for lifting operation.

Multi plates can not be lifted, only lift one piece of clamp one time. Up the lock lever to tighten lock spring when it under loading. Down the lock lever to loose lock spring, when you could unload.

Tested load is 2 times of working load, minimum breaking strength≥ 5 times of working load.

With lock spring during the clamp non-work condition, locking device going in nature step-up, put the object in the clamp, the strength becomes the proportion enhancement.

CN

CN EN

EN

Your location:

Your location:

Home

Home Tel

Tel Product

Product